Introduction TO GX53 Metallographic microscope

1、Overview

● Quickly Analyze Thick, Large SampleMaterials

Designed for use in the steel, automotive,electronics, and other manufacturing industries, the GX53 microscope deliverscrisp images that can be difficult to capture using conventional microscopyobservation methods. When combined with OLYMPUS Stream image analysis software,the microscope streamlines the inspection process from observation to imageanalysis and reporting.

● Fast Inspections, Advanced Functionality

Quickly observe, measure, and analyze metallurgicalstructures.

Advanced Analysis Tools

1. Combined observation methods produceexceptional images

2. Easily create panoramic images

3. Create all-in-focus images

4. Capture both bright and dark areas

Optimized for Material Science

1. Software designed for materials science

2. Metallurgical analysis that complieswith industrial standards

● Userfriendly

Even novice operators can comfortably makeobservations, analyze results, and create reports.

1. Easily restore microscope settings

2. User guidance helps simplify advancedanalysis

3. Efficient report generation

● Advanced Imaging Technology

Our proven optics and imaging technologydeliver clear images and reliable results.

1. Reliable optical performance: wavefrontaberration control

2. Clear images: image shading correction

3. Consistent color temperature:high-intensity white LED illumination

4. Precise measurements: autocalibration

● Modular

Choose the components you need for yourapplication.

1. Build your system your way: fullycustomizable system with a variety of optional components

2、Observation

● Advanced Analysis Tools

The GX53 microscope’s various observationcapabilities provide clear, sharp images, so you can reliably detect defects inyour samples. OLYMPUS Stream image analysis software's new illuminationtechniques and image acquisition options give you more choices for evaluatingyour samples and documenting your findings.

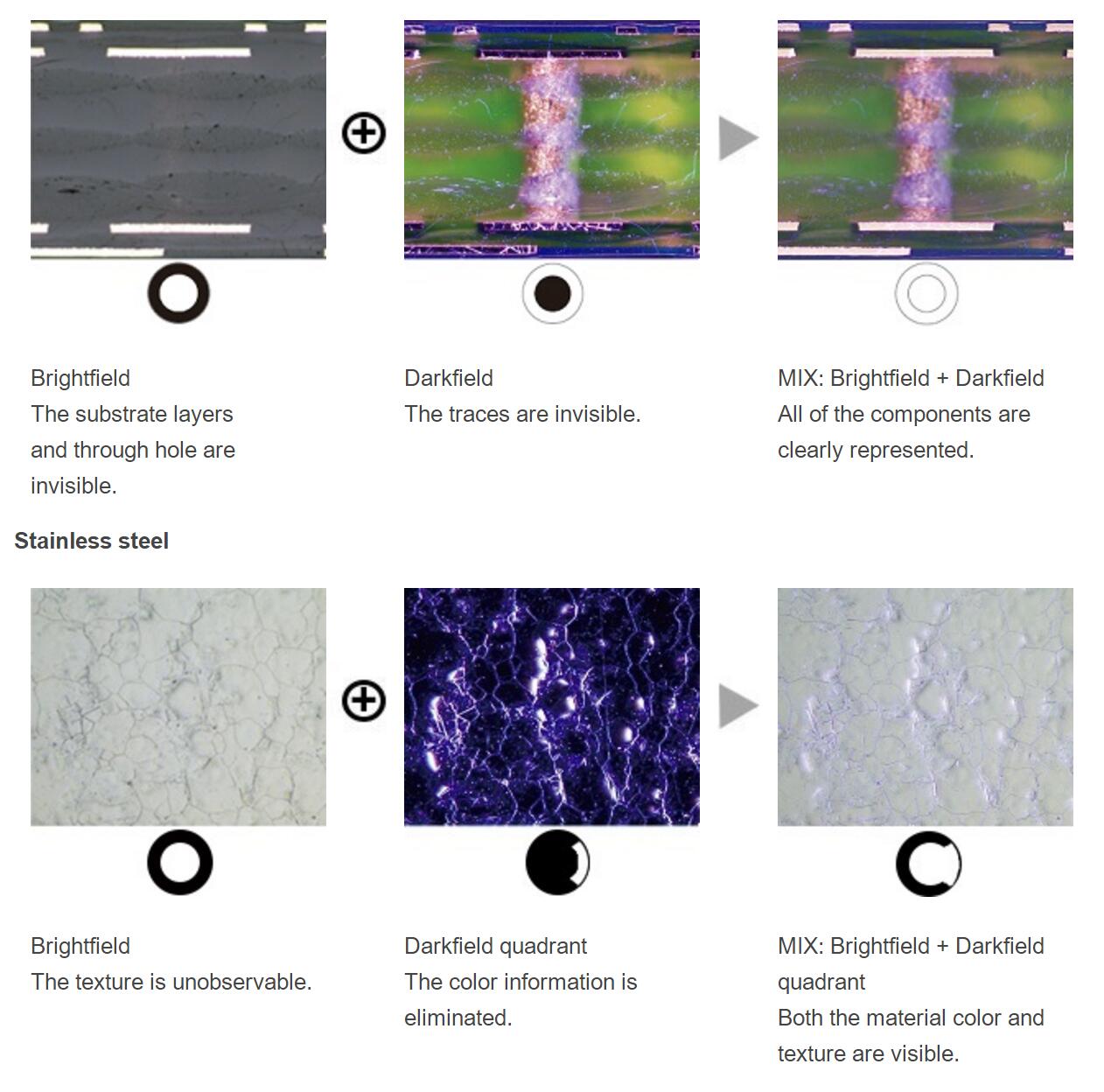

● The Invisible Becomes Visible: MIXTechnology

MIX technology combines darkfield withanother observation method, such as brightfield or polarization, to enable youto view samples that are difficult to see with conventional microscopes. Thecircular LED illuminator has a directional darkfield function where one or morequadrants are illuminated at a given time, reducing a sample’s halation tobetter visualize surface texture.

Cross-section of a printed circuit board

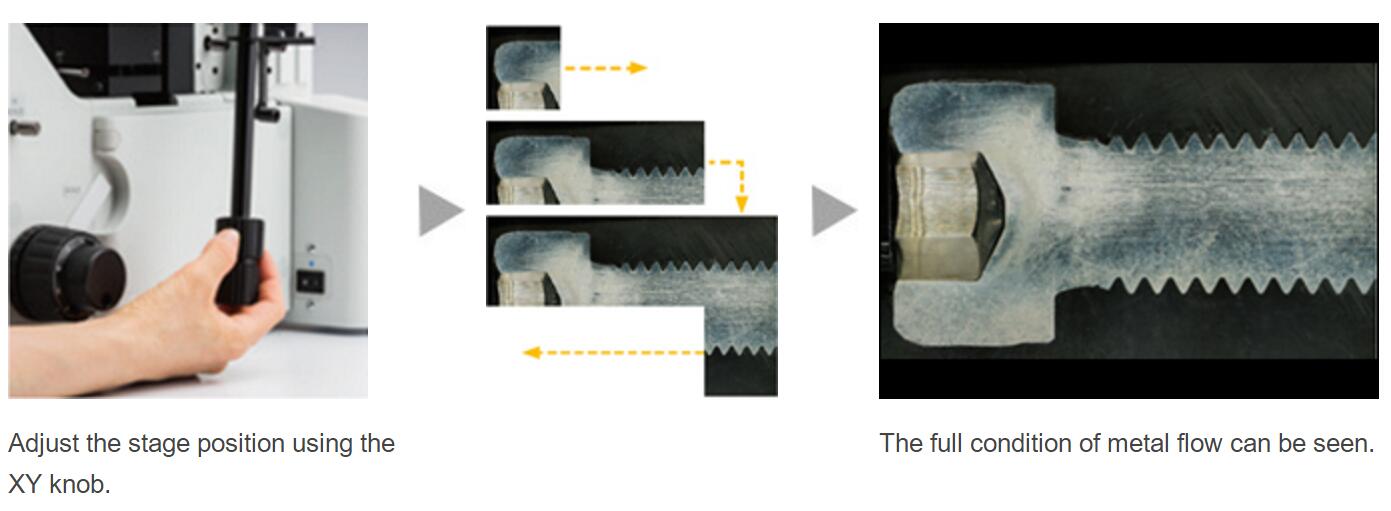

● Easily Create Panoramic Images: Instant MIA

With multiple image alignment (MIA), youcan stitch images together simply by moving the XY knobs on the manual stage—amotorized stage is optional. OLYMPUS Stream software uses pattern recognitionto generate a panoramic image, making it ideal for inspecting carburizing andmetal flow conditions.

Metal flow of a bolt

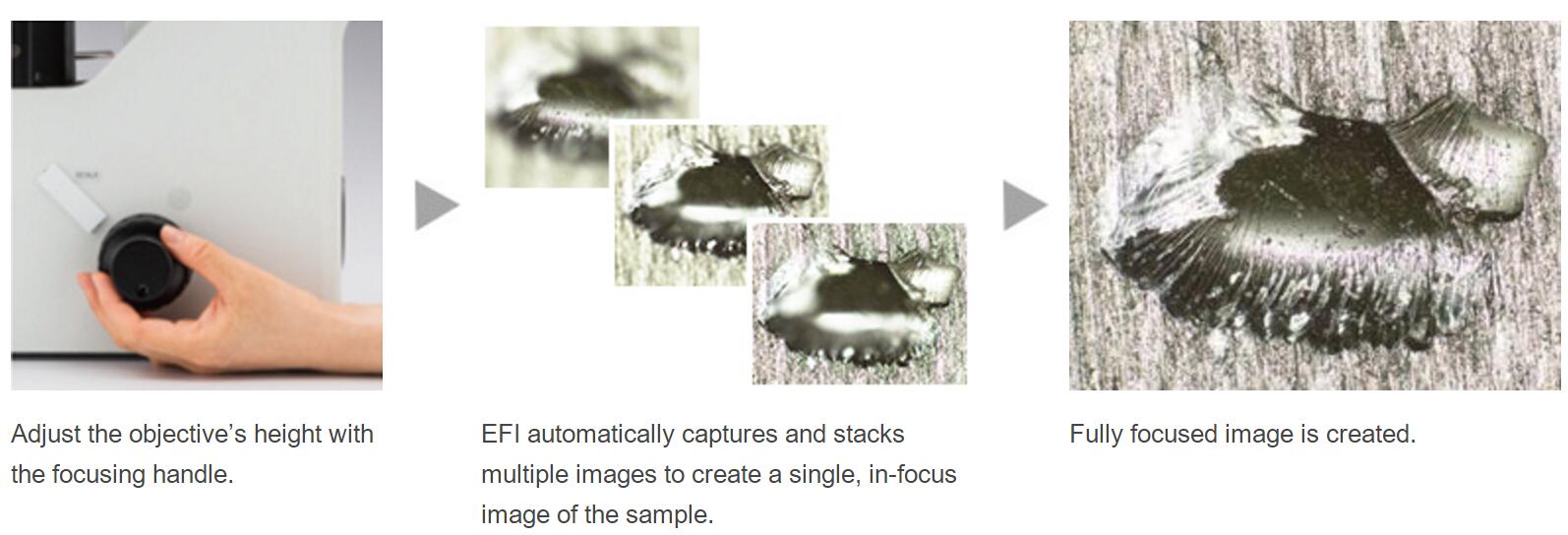

● Create All-in-Focus Images: EFI

OLYMPUS Stream software’s extended focusimaging (EFI) function captures images of samples whose height extends beyondthe depth of focus. EFI stacks these images together to create a singleall-in-focus image of the sample. Even when analyzing a cross-section samplewith an uneven surface, EFI creates fully-focused images.

EFI works with either a manual or motorizedZ-axis and creates a height map to visualize structures.

Resin parts

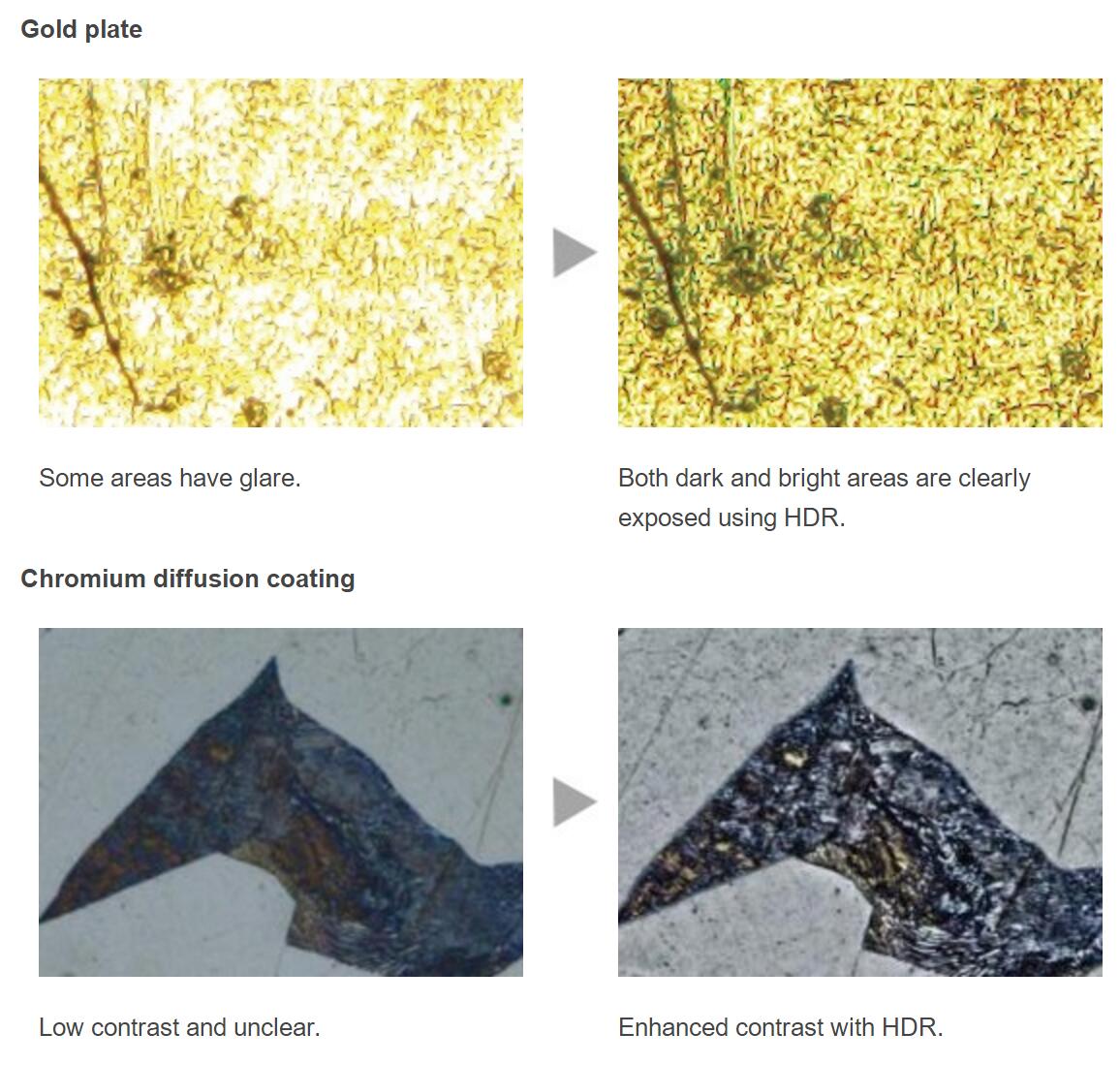

● Capture Both Bright and Dark Areas UsingHDR

Using advanced image processing, highdynamic range (HDR) adjusts for differences in brightness within an image toreduce glare. It also helps boost the contrast in low-contrast images. HDR canbe used to observe minute structures in electric devices and identify metallicgrain boundaries.

3、Analysis

● OLYMPUS Stream Software – Optimized forMaterials Science

Together, the GX53 microscope and OLYMPUSStream software support metallurgical analysis methods that comply withdifferent industrial standards. With step-by-step operator guidance, users cananalyze their samples quickly and easily.

● Particle Analysis – Count and MeasureSolution

The Count and Measure solution usesadvanced threshold methods to reliably separate objects, such as particles andscratches, from the background. More than 50 different object measurement andclassification parameters are available including shape, size, position, andpixel properties.

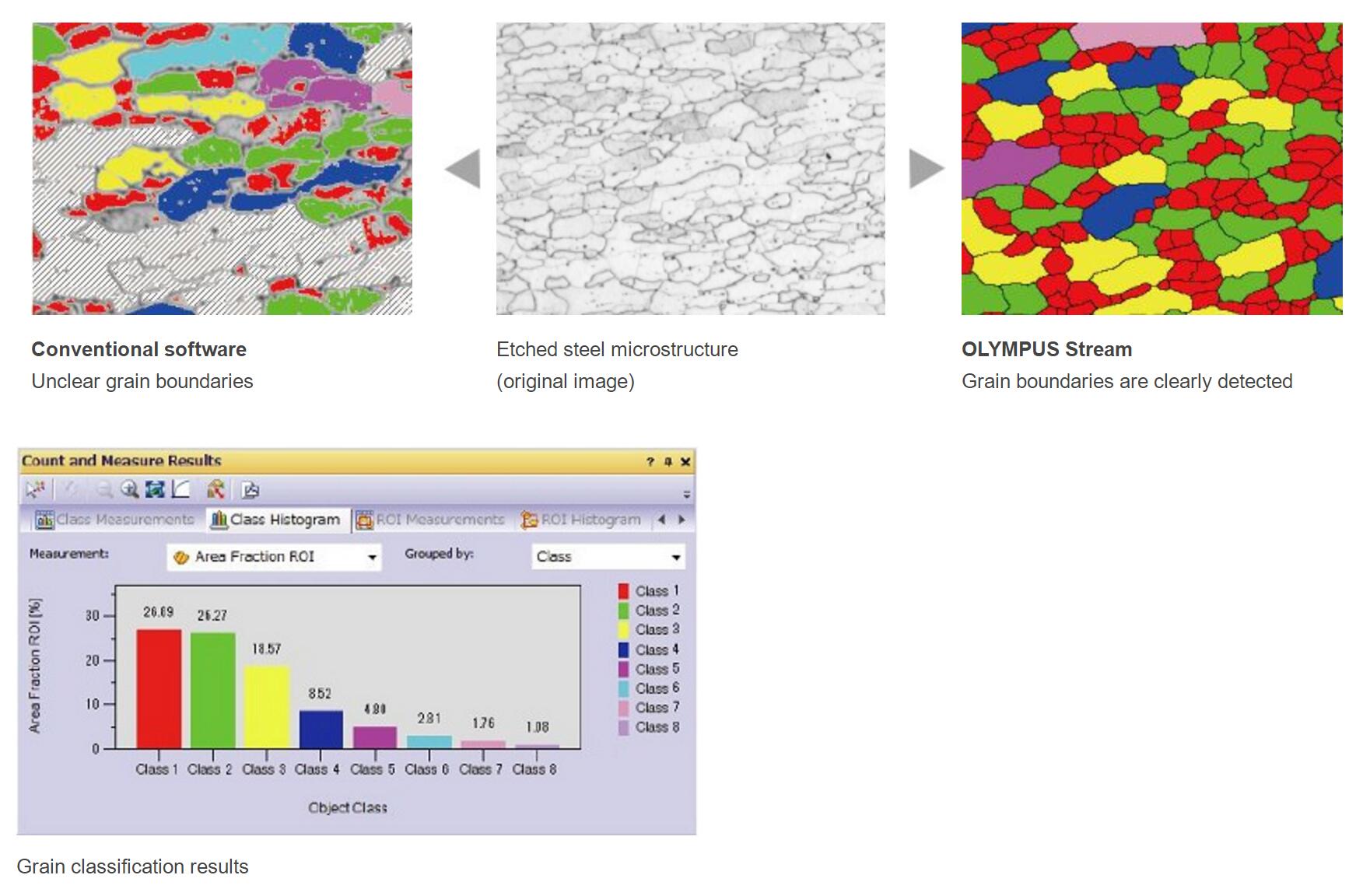

● Grain Sizing in a Microstructure

Measure the grain size and analyze themicrostructure of aluminum, steel crystal structures, such as ferrite andaustenite, and other metals.

Supported standards: ISO, GOST, ASTM, DIN, JIS, GB/T

Microstructure of ferritic grains

● Evaluating Graphite Nodularity

Evaluate the graphite nodularity andcontent in cast iron samples (nodular and vermicular). Classify the form,distribution, and size of graphite nodes.

Supported standards: ISO, NF, ASTM, KS, JIS, GB/T

Ductile cast iron showing nodular graphite

Cast iron solution

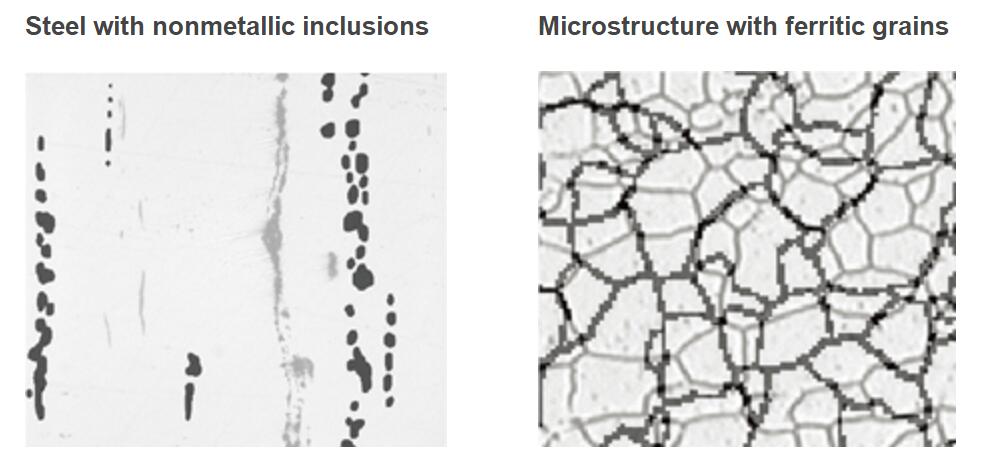

● Rating Nonmetallic Inclusion Content inHigh-Purity Steel

Classify nonmetallic inclusions using animage of the worst field or worst inclusion found manually in the sample.

Supported standards: ISO, EN, ASTM, DIN, JIS, GB/T, UNI

Steel with nonmetallic inclusions

Inclusion worst field solution

● Compare Images of Your Sample and ReferenceImages

Easily compare live or still images withauto-scaled reference images. This solution includes reference images inaccordance with various standards (additional reference images can be purchasedseparately). Multiple modes are supported, including live overlay display andside-by-side comparison.

Supported standards: ISO, EN, ASTM, DIN, SEP

3、Sharing

● Simple and Efficient Inspections

Use the GX53 microscope andOLYMPUS Stream software to acquire images of diverse samples, conduct avariety of analyses, and generate professional reports.

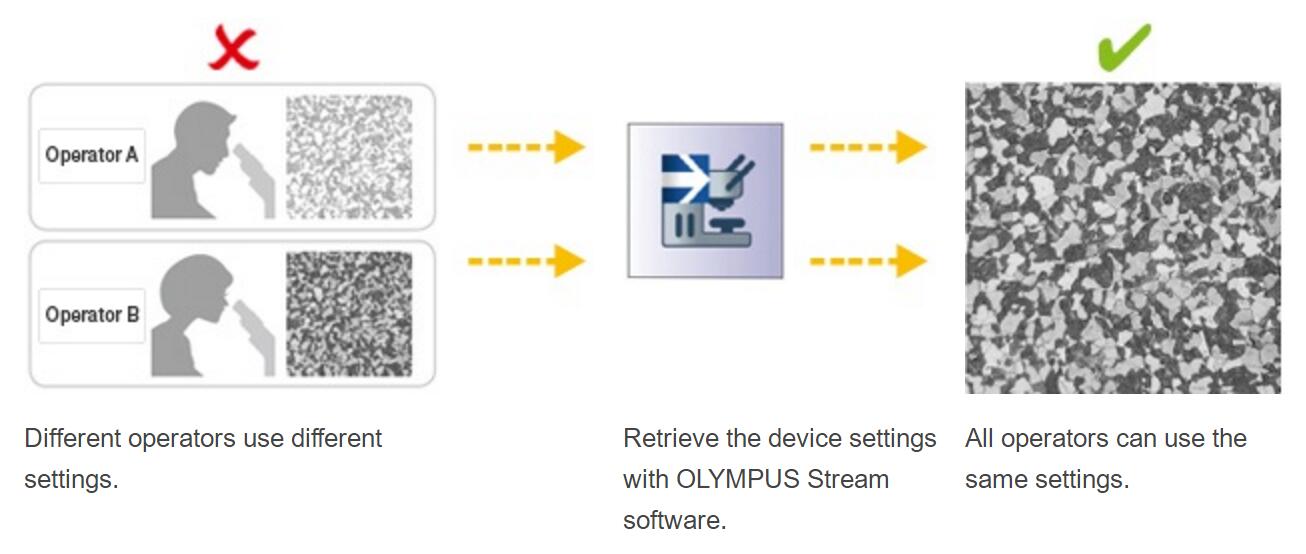

● Easily Restore Microscope Settings: CodedHardware

Coded functions integrate the microscope’shardware settings with OLYMPUS Stream image analysis software. The observationmethod, illumination intensity, and magnification can be recorded and storedwith the associated images. The settings are easily reproduced so thatdifferent operators can conduct the same quality inspections with limitedtraining.

Different operators use different settings. Retrieve the device settings with OLYMPUS Stream software. All operators can use the same settings.

● User Guidance Helps Simplify AdvancedAnalysis

The software guides users step-by-stepthrough an inspection process that complies with the chosen industrialstandard. Operators can conduct advanced analysis simply by following theon-screen guidance.

● Efficient Report Generation

Creating a report can often take longerthan capturing the image and taking the measurements. OLYMPUS Stream softwareprovides intuitive report creation to repeatedly produce sophisticated reportsbased on predefined templates.

Technical Specifications

Optical systemOptical system | UIS2 optical system (infinity-corrected) | |

Microscope frame | Reflected light illumination | Manual brightfield/darkfield selection by mirror unit |

Transmitted light illumination | Stand for transmitted light (IX2-ILL100: with field stop) is required | |

Imprinting of scale | All ports reversed positions (up/down) from observation positions seen through the eyepiece | |

Output front port (optional) | Camera and DP system (reversed image, special camera adapter for GX) | |

Output side port (optional) | Camera, DP system (upright image) | |

Electrical system | Reflected light illumination | |

Focus | Rack and pinion with roller guide | |

Tubes | Widefield (FN 22) | Inverted: binocular (U-BI90, U-BI90CT), trinocular (U-TR30H-2), tilting binocular (U-TBI90) |

Nosepiece | Brightfield Holes: 4 to 7 pcs, Type: Manual/Coded, Centering: Enabled/Disabled | |

Stage | Right handle stage for GX (X/Y stroke: 50 × 50 mm, max. load 5 kg) | |

Weight | Approx. 25 kg (microscope frame 20 kg) | |

Environment | ・Indoor use | |